The manufacturing sector is undergoing a transformative shift as Artificial Intelligence (AI) becomes integral to Industry 4.0. In 2025, manufacturers are leveraging AI to enhance efficiency, reduce costs, and stay competitive in a rapidly evolving market. From predictive maintenance to collaborative robots, AI is redefining production processes and supply chain management.

Industry 4.0, marked by smart manufacturing, gains greater momentum when combined with AI. With technologies like AI, ML, IoT, and Cloud at its core, the goal is to boost efficiency, maximize ROI, and stay competitive. Across industries and generations, the discourse on AI and Generative AI (GenAI) continues to evolve, significantly impacting the manufacturing sector.

The AI in manufacturing market is projected to grow to USD 20.8 billion by 2028, reflecting a CAGR of 45.6%.

This blog explores the fundamentals of AI in manufacturing, investigating its transformative applications in predictive maintenance, quality control, and supply chain optimization.

Transforming Manufacturing with AI Technologies

In real-world scenarios, bigger players in the industry are making the most of this technology, while several smaller players need to realize the ease of getting their hands on AI solutions that can readily bring high value with lower costs.

With the rise of Industrial IoT (IIoT) and smart factories, massive volumes of data are generated daily, making AI-powered solutions like Machine Learning and Deep Learning essential tools for intelligent data analysis. From predictive maintenance that minimizes downtime and optimizes production costs to real-time quality control and process automation, AI is becoming a critical driver of Industry 4.0.

Calsoft, being a technology-first company, has translated successful digital transformations across industries. Our expertise in Gen AI, analytics & ML can be deployed to gain operational efficiency.

Download the brochure to gain more insights.

The more Gen AI is trained through continuous trials and innovation, the more it can deliver game-changing solutions to elevate manufacturing operations and streamline production workflows.

Our team of experienced professionals has a deep understanding of the manufacturing industry, and its digital transformation needs. We provide innovative solutions that help our customers attain smart factory goals. Expertise in digital platform & application development, testing, modernization, cloud solutions, and AI/ML helps our customers stay ahead of the competition by bringing visibility, intelligence, control, predictability, security, and efficiency to the traditional manufacturing setup.

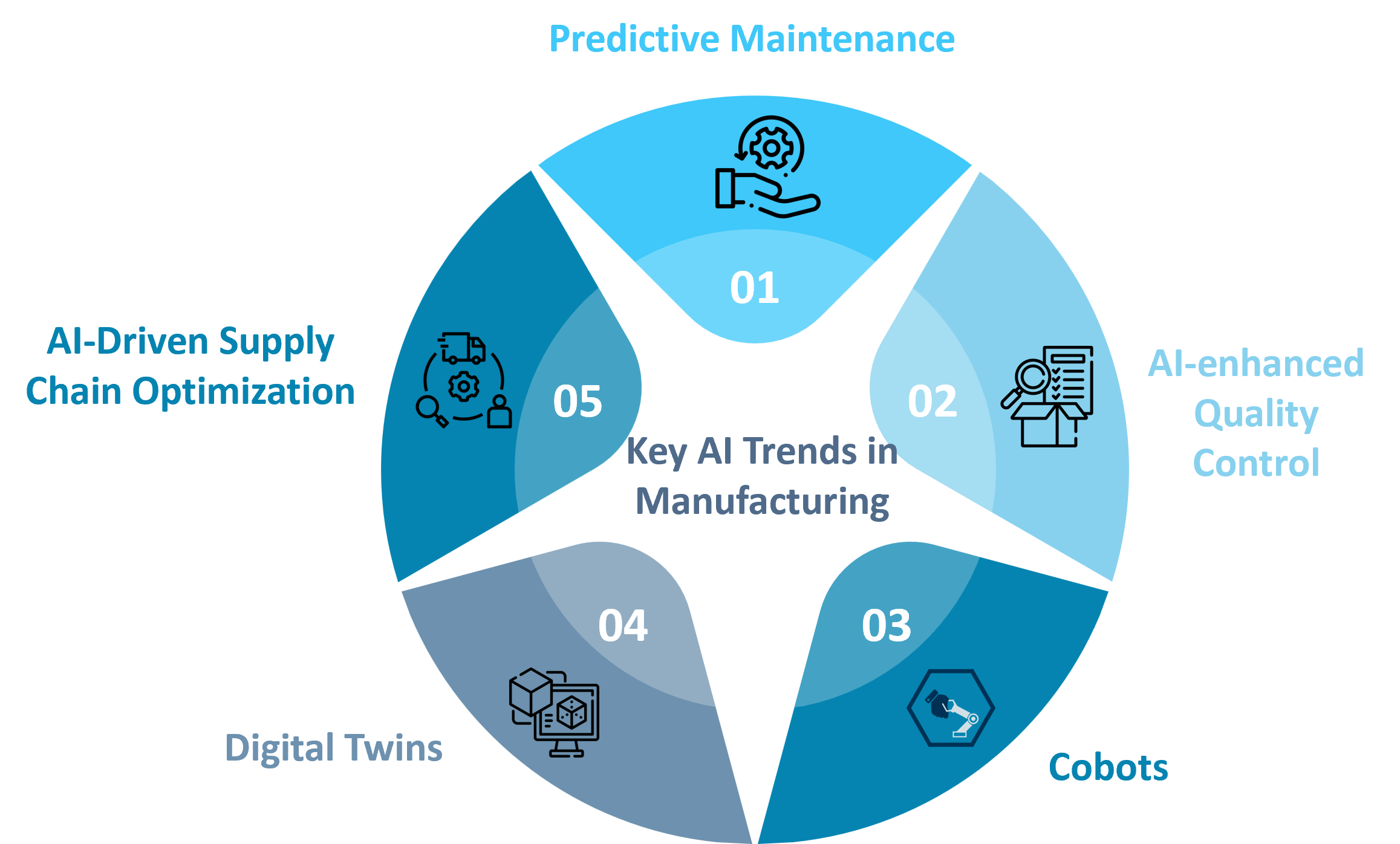

Key Trends Shaping AI-Driven Manufacturing

AI-driven solutions help manufacturers predict equipment issues in advance, enabling proactive maintenance and reducing unplanned downtime. AI analyses vast data to deliver key insights, helping manufacturing leaders make smarter decisions and drive continuous improvement.

For deeper insights into how AI is steering Industry 4.0, read the blog How AI is Steering Industry 4.0: Transforming the Manufacturing Sector.

- Predictive Maintenance: Minimizing Downtime

AI-powered predictive maintenance is revolutionizing equipment management. By analysing real-time data from sensors, AI algorithms can forecast equipment failures before they occur, allowing for timely interventions. This proactive approach reduces unplanned downtime and maintenance costs. According to McKinsey, AI-driven predictive maintenance can cut maintenance costs by up to 15% and reduce machine downtime by up to 50%.

- AI-Enhanced Quality Control

Traditional quality inspection methods are being supplanted by AI-driven computer vision systems. These systems can detect defects with high accuracy and speed, ensuring consistent product quality. This cutting-edge technology is crucial for ensuring that only top-quality products reach the market, which helps minimize waste and enhance customer satisfaction.

- Collaborative Robots (Cobots) in the Workforce

Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. Equipped with AI, cobots can adapt to dynamic production environments, handling tasks such as assembly, packaging, and quality inspection.

- Digital Twins: Virtualizing the Production Line

Digital twin technology creates virtual replicas of physical assets, enabling real-time monitoring and simulation. Manufacturers use digital twins to optimize processes, predict outcomes, and reduce operational risks.

- AI-Driven Supply Chain Optimization

AI is enhancing supply chain management by providing real-time tracking, demand forecasting, and inventory optimization. By analyzing data from IoT devices and other sources, AI helps manufacturers respond swiftly to disruptions, ensuring efficient logistics and distribution. This leads to improved customer satisfaction and reduces operational costs. Read the blog to learn how Gen AI is transforming the manufacturing landscape, enabling smarter, data-driven operations. Gen AI Applications in Supply Chain Management

Conclusion

As we navigate through 2025, AI continues to be a driving force in transforming the manufacturing landscape. From enhancing equipment reliability to optimizing supply chains, AI’s role in Industry 4.0 is pivotal. Manufacturers embracing these technologies are poised to achieve greater efficiency, agility, and competitiveness in the global market.